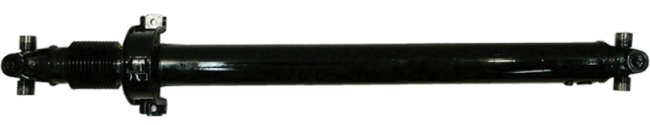

What is a Driveshaft?

The driveshaft, also known as the propeller shaft or prop shaft, is a vital component of a machine's drivetrain system. It consists of a tube with connectors, known as yokes, on each end, which are attached to U-joints. These U-joints serve as the link between the driveshaft and the engine or other stationary parts of the vehicle. The driveshaft is made up of several tubes, bearings, and yokes, all working together to transmit power and enable smooth movement.

What Does It Do?

The primary function of the driveshaft is to transfer power from the engine to the rear of the machine, connecting it to the differential. This is achieved through a series of rotations:

-

Engine Spinning: The engine generates power and spins the gears in the transmission.

-

Transmission to Driveshaft: The spinning power is transferred to the driveshaft through the transmission.

-

Locking into the Differential: The driveshaft is connected to the differential, allowing the torque to be transmitted to the machines' wheels or tracks.

The driveshaft plays a crucial role in absorbing movements and enabling different parts of the vehicle to move independently without damaging the drivetrain components. By efficiently transmitting power from the engine to the wheels or tracks, the driveshaft enables the machine to move and perform various tasks effectively.

Signs of a Failing Driveshaft

- Vibrations: Intense shaking from underneath the machine, which can be the most common sign.

- Shuddering: The machine shudders when accelerating.

- Clunking: Loud clunking noises, which can be caused by worn-out u-joints.

- Squeaking: Squeaking noises, which can be caused by a lack of u-joint lubrication.

- Turning problems: Difficulty turning the machine.

- Universal joint movement: Movement in the universal joint.

Maintaining the Driveshaft

To ensure optimal performance and longevity of the driveshaft, regular maintenance is essential. Some key maintenance tasks include:

-

Lubrication: Properly lubricating the U-joints and bearings helps reduce friction and wear, extending the lifespan of the driveshaft.

-

Inspection: Regularly inspecting the driveshaft for signs of damage, wear, or misalignment can help identify potential issues early on and prevent costly repairs.

-

Replacement: If any component of the driveshaft, such as U-joints or bearings, shows signs of wear or damage, timely replacement is crucial to prevent further damage and maintain the driveshaft's efficiency.

-

Balancing: Ensuring the driveshaft is correctly balanced is vital to minimize vibrations and improve overall drivetrain performance.

By taking these maintenance measures, you can keep the driveshaft in top condition, ensuring a smooth and reliable transfer of power from the engine to the wheels or tracks.

Need a driveshaft or other driveline component for your machine? Click below to get a quote today!